Decoration process

Screen printing, also known as body printing, is the most common method of printing on plastics. In this process, ink is printed onto the plastic through a fine-mesh screen using a squeegee. We are able to realize your design wishes. We use UV screen printing and can therefore print up to three colors in one pass.

The finishing process is suitable for cans, lids and bottles in both round and oval shapes.

The advantages include the variety of designs (round, square, oval, with handle, etc.) and flexible production output.

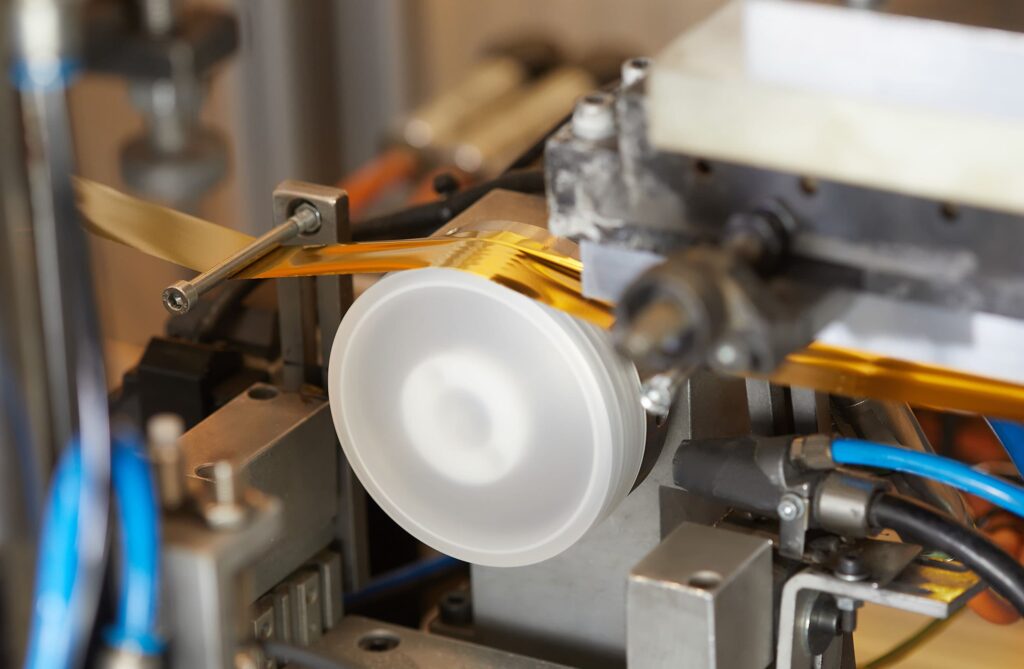

Hot foil stamping

Highly decorative foils are hot-stamped as round or head surface embossing in a wide variety of designs and shapes. The print motif is removed from the highly decorative metallic foil using a heated stamp and embossed onto the packaging body.

We use this process for a range of packaging solutions such as cans, lids and bottles.

This unique finishing process gives your product a metallic sheen and a striking effect.

Paintwork

Amazing things are possible! We achieve visual and tactile effects using the spray painting process. We use matt lacquer, soft-touch lacquer, rubber-effect lacquer and pearl-effect lacquer, mostly on a water-soluble basis.

Conveyor belts or automated transport systems are used to guide the usually pre-treated plastic parts through the painting process. This enables continuous and efficient painting. The painting process is usually followed by a drying phase to harden the paint and ensure a durable, resistant surface.

If you opt for plastic packaging with a special coating, you will stand out from the competition. Your product gains brand identity and the aesthetics are refined. We offer this process as a full service with our partners.

Metallizing

Metallization is a special finishing process in which highly decorative top coats are applied to give the product a higher quality look and feel.

Various processes have been tried and tested for the metallization of plastics:

- PVD (physical vapor deposition): Sputter deposition, thermal evaporation

- CVD (chemical vapor deposition)

- Thermal spraying

- Plastic electroplating

The metallization process gives your packaging solutions an elegant design. An exclusive aesthetic is created. We offer this process as a full service with our partners.

Your individual solution

Our specialists will be happy to advise you on the individual implementation options so that your product stands out from the crowd and thus emphasizes your brand identity.

As a premium manufacturer of plastic packaging such as jars, bottles and closures, we focus on sustainability. We pay attention to economic efficiency without neglecting ecologically compatible and socially justifiable aspects.

We develop sustainable and resource-saving cosmetics packaging.

To achieve this, we attach great importance to reducing both weight and material consumption. This does not compromise the performance of the product.

Reliable, modern machines, high-quality raw materials and short, energy-saving transportation routes enable efficient production processes at reduced energy costs.