We are a company that convinces

We are one of the leading manufacturers of plastic jars, bottles and closures for the cosmetics and pharmaceutical industries.

Hopf Packaging works with its customers to develop customized packaging solutions, also with an elegant design.

Our trained specialists produce cosmetics packaging from a wide variety of materials.

We have the option of using recycled materials in production.

Our strengths lie in customer-oriented thinking and action combined with short decision-making processes.

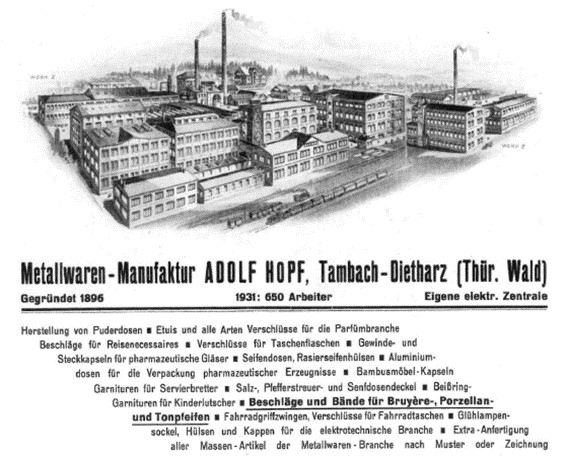

From metal goods manufacturer

to plastics pioneer.

1896

Founding of the metal goods manufacturer Adolf Hopf in Tambach-Dietharz/Thuringia

Production of lids for tobacco pipes, fittings and rings and other small metal parts

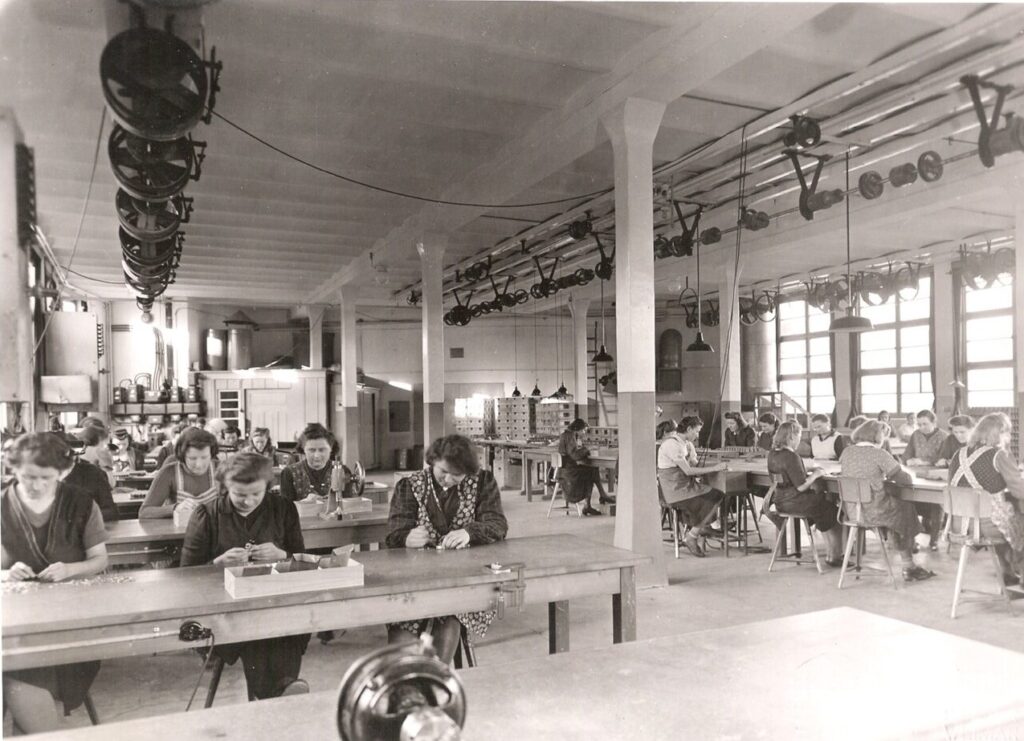

1927

Pioneer in plastics processing, development of tools and special machines

1929

Foundation of a branch plant in England

1935

Production of plastic bottles, closures and cans

1946

War-related new start in Nördlingen in Bavaria/Swabia as Metallwerke Adolf Hopf with company headquarters at Bürgermeister-Reiger-Straße 15

1951

Since then, the training of skilled workers has been just as central to the company’s philosophy as their further qualification

1952

The company moves to its current location at Wemdinger Straße 13

1960

Introduction and continuous expansion of injection molding technology

Packaging materials are produced for the chemical, pharmaceutical, food and cosmetics industries.

In addition to compression and injection molding, bottle production using the extrusion blow molding process and the hot foil stamping and screen printing decoration processes were added over time

1981

Renamed Kunststoffwerke Adolf Hopf

2000

Construction of a new production hall

Start of large-scale production (inline production)

2012

Extension building with expansion of large-scale production

2013

Start of cooperation with Siepe GmbH in Sindorf/Kerpen

2015

Change of name to Hopf Packaging GmbH

2018

Introduction of an energy management system in accordance with DIN EN ISO 50001:2011

2020

Certification of the energy management system in accordance with DIN EN ISO 50001:2018

2022

Installation of a PV system with a total output of 183.75 kWp

2024

Expansion of the PV system by a further 115.32 kWp

Hopf, the movie

We have been one of the leading manufacturers of jars, bottles and closures for the pharmaceutical and cosmetics industry since 1896.

That’s why we know that standard is not good enough. Everything is feasible. Every solution is unique. Otherwise it’s not from Hopf.

We’ve been making history – since 1896.

Our mission statement – Our corporate policy

Hopf Packaging GmbH is an internationally oriented and operating German medium-sized company. We take environmental and energy-relevant aspects into account in all our actions. Our core values, born of tradition, are optimum quality, competence and reliability, combined with consideration for other living beings, conservation of resources and the environment. All employees in the company stand for this with their personality, experience, team spirit and willingness to act and shape responsibly.

We are aware of our responsibility towards our internal and external partners and fulfill the expectations placed on us, such as binding, legal and our own obligations.

In order to be able to control and steer these in a targeted manner, we focus on the continuous improvement of our products, services and processes, with the aim of achieving the best results.

We have set ourselves the following priorities for this:

- high quality of our products and services

- Improvement in specific energy consumption

- high quality of our products and services

- minimize the environmental impact of our actions as much as possible

Experience and innovation

We are a premium manufacturer of plastic cosmetics packaging. We have been impressing customers with our performance and quality since 1896! Our product portfolio includes jars, bottles and closures.

We supply our products worldwide to well-known customers in the cosmetics and pharmaceutical industries.

Our specialists realize unique solutions for you.

Customized design solutions

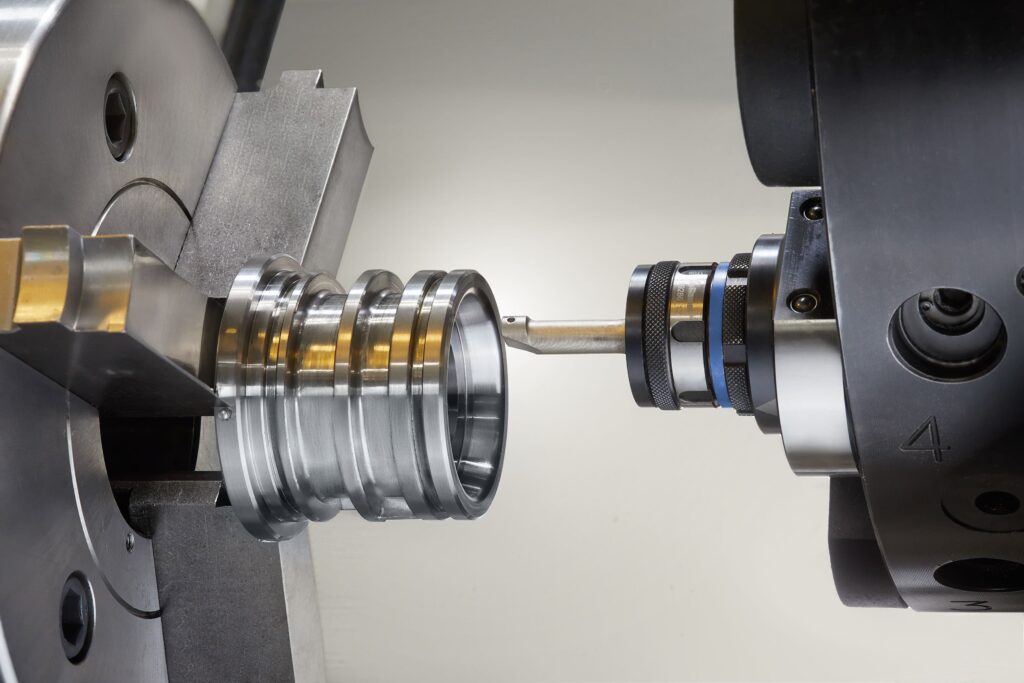

Our experienced specialists are experts in their fields. They can turn your design requirements into construction drawings for injection mouldingand hollow blow moulds.

They use the latest CAD/CAM programs for this. If required, we can provide you with illustrative models using our in-house 3D printer.

State-of-the-art production processes make it possible

We produce plastic jars and matching closures in two different ways. For large batch sizes, we use the inline process, also known as fully automated production.

We produce smaller quantities of products in small batches.

Assembly, finishing and packaging are part of our service in the respective production processes.

We produce plastic bottles with a volume of 3 ml to max. 1,000 ml using the hollow blow molding process.

Our specialist staff use various manufacturing processes to realize individual customer requirements. We use commercially available plastics for our high-quality cosmetics packaging.

Quality – 7 goals are crucial for us

Our corporate policy focuses on customer satisfaction.

We have set ourselves the following goals in order to meet customer requirements:

- we manufacture high-quality products

- We use the technical possibilities while adhering to social norms and values

- We are a competent and reliable partner for our customers

- We attach great importance to manufacturing in accordance with the legal requirements in terms of approval and design

- We maintain long-term supply relationships with our suppliers and thus ensure a reliable supply.

- we identify errors, analyze them and initiate suitable corrective measures

- we work continuously to improve our processes and products

Quality and certifications

Plastic packaging

The latest technologies, qualified employees, certifications in accordance with international standards – this is how we ensure that our customers always receive what they rightly expect: customized, high-quality packaging.

Assured sustainability

We operate fundamentally both socially and ecologically responsible.

We ensure good working conditions and fair pay.

We use natural resources efficiently and avoid ingredients that are harmful to the environment or health.

Genuine sustainability is both an obligation and a challenge for us.

ISO 9001:2015 quality management system

Our commitment to quality assurance is our top priority and the primary responsibility of every employee. We see the documentation of our actions in accordance with DIN EN ISO 9001:2015 as a fundamental matter of course. The scope includes all areas of customer perception. Consequently, the measure of quality is not only the consistently high processing quality of our products, but also the quality of our service. Creativity and flexibility, reliability, speed and friendliness are essential prerequisites for us and at the same time an expression of high service quality. Both our customers and our company benefit from our effectiveness.

Download: Hopf Certificate 9001, German – 2025

Energy efficiency according to ISO 50001:2018

Thanks to our energy management system according to ISO 50001:2018 As an integrated management system with ISO 9001:2015, we can improve our energy-related performance. All legal and other framework conditions are taken into account and complied with.

This ranges from procurement and use to reducing consumption. We analyze all processes from the point of view of Energy efficiency and improve them wherever possible. It is also worth mentioning that we have already invested in renewable energy and are planning further expansion.

GKV Code of Conduct

It is a matter of course for us to know and observe the applicable rules and prohibitions in the company. Our company has adopted the Association’s Code of Conduct ( Code of Conduct) as binding for us.

This Code is a voluntary agreement with which we want to ensure compliance with global requirements for ethical and moral behavior as well as the requirements of proper conduct under competition and antitrust law with the member companies that join. We strive for this, fair and sustainable standards in our dealings with suppliers and customers as well as our own employees.

Since its foundation in 2007 EcoVadis has become the world’s largest and most trusted provider of sustainability ratings for companies.

As a premium manufacturer of cosmetics packaging, it is a matter of course for us to undergo a rating. Our efforts in various areas of sustainability stand out. As a medium-sized company, we are proud of our award.