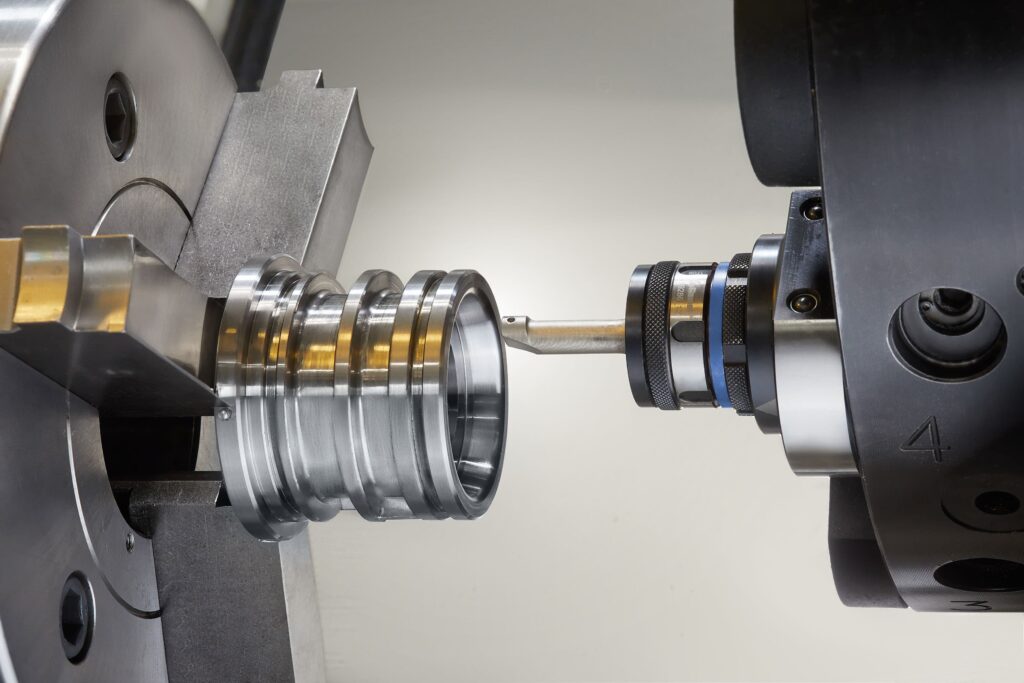

Toolmaking

You have different requirements for your individual packaging. Our production facilities are correspondingly versatile and flexible to use. We use state-of-the-art technologies and production processes. Our in-house toolmaking and maintenance departments are the foundation for flexibility, short response times and the high quality of our product range.

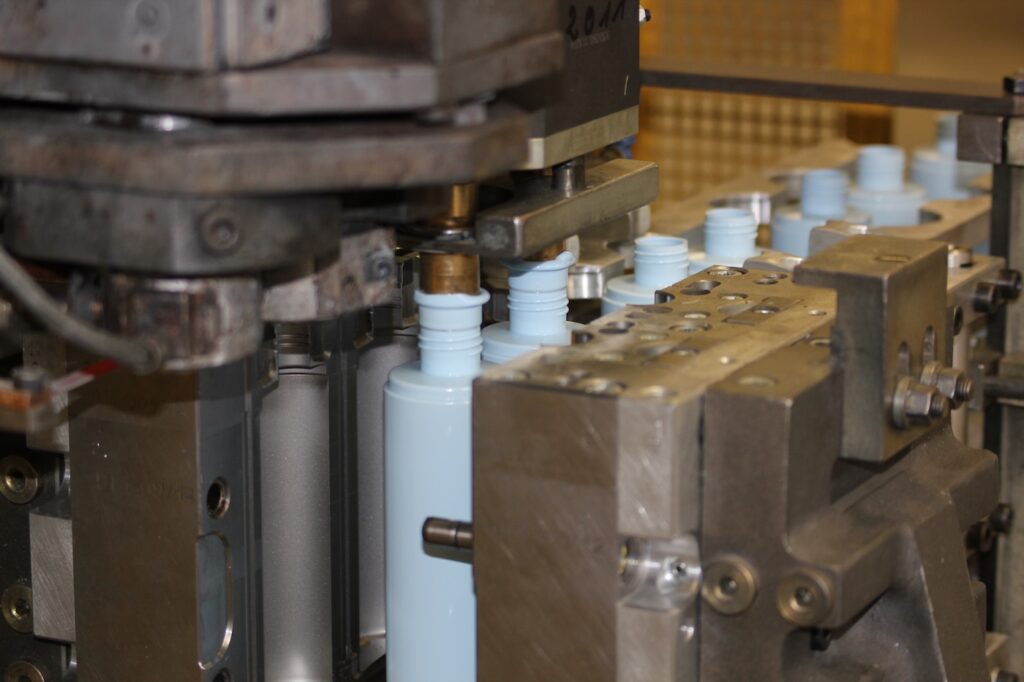

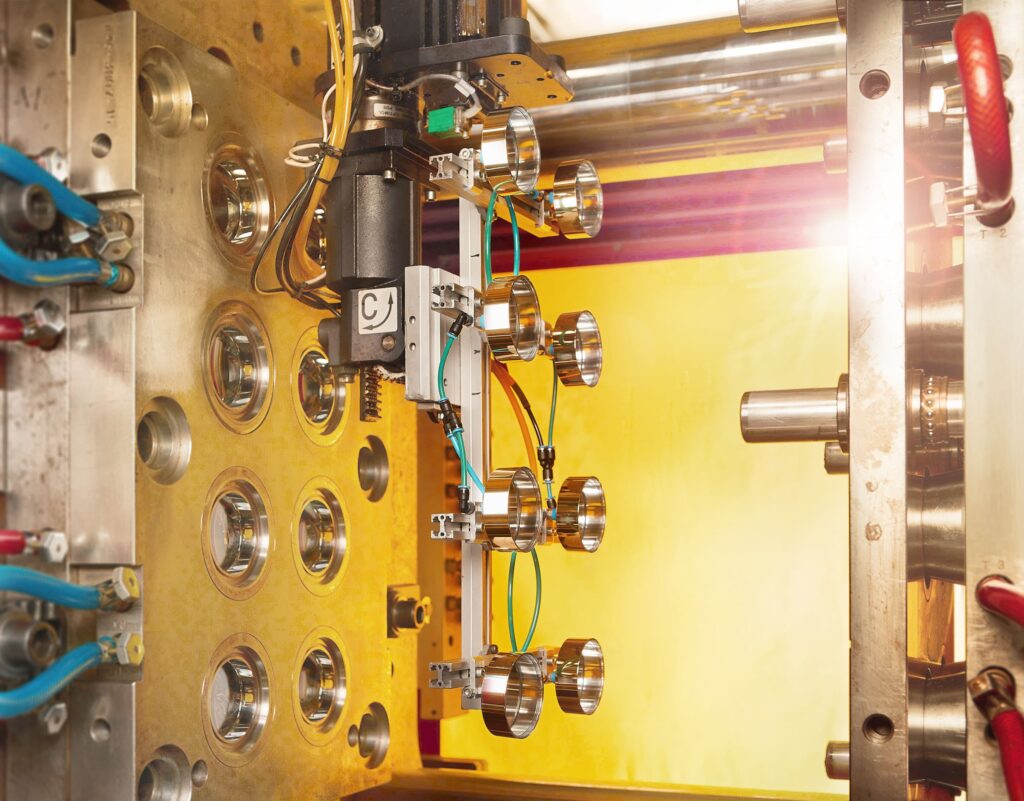

Injection molding

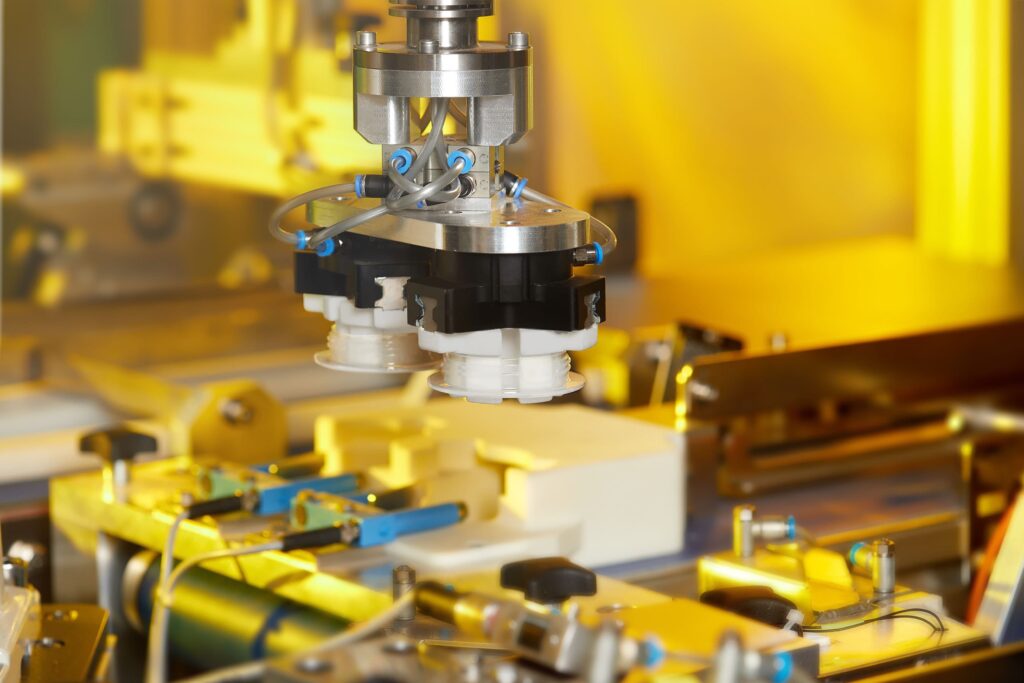

A large fleet of injection molding machines in the 50 – 350 t range enables us to produce your tailor-made packaging.

Our experienced employees are proficient in both inline production and small batch production. In the inline process, assembly, finishing and packaging are integrated with a high degree of automation and vertical integration (in line) at .

In the injection molding process, the plastic mass (granulate) is injected under pressure into a mold and cooled. This production process is particularly suitable for preforms, jars and closures.

The advantage lies in the almost unlimited choice of shapes and surfaces.

In addition, our cooperation partner Siepe has high-performance injection molding machines that make it possible to produce preforms from PET and PP.

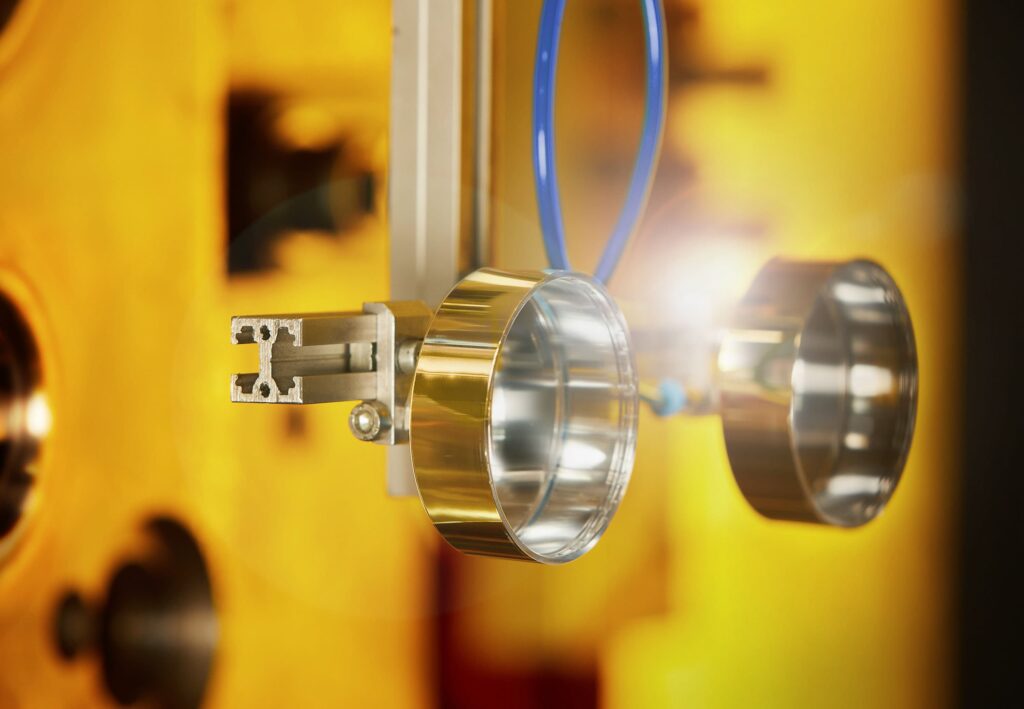

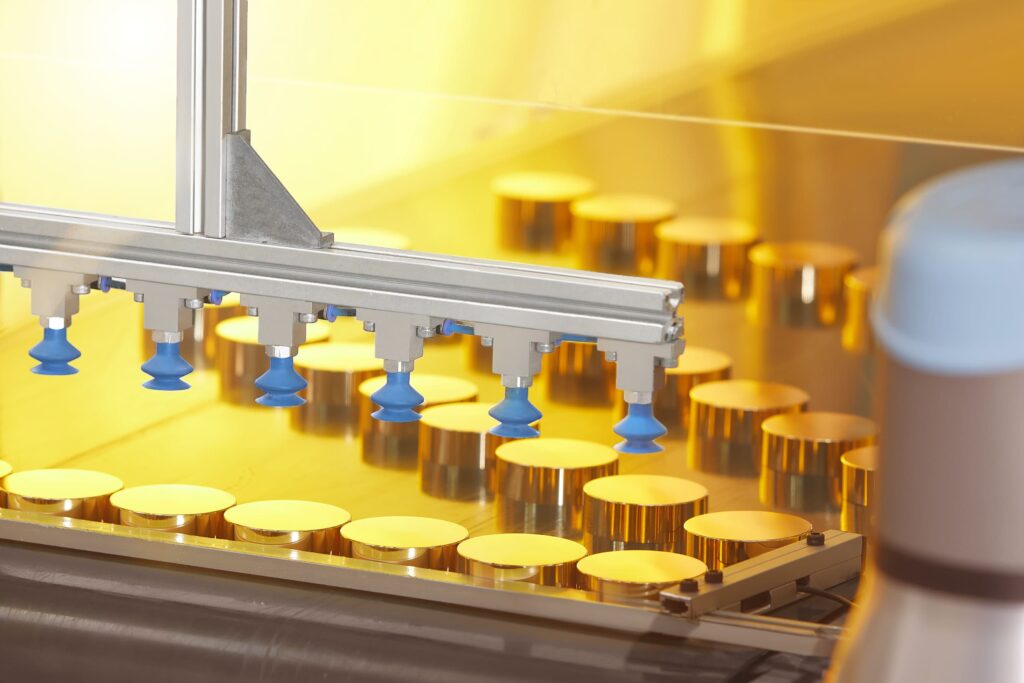

Extrusion blow molding

We can produce bottles with a volume of 3 ml – 1,000 ml in the field of extrusion blow molding (monolayer, multilayer, visible strips). We use commercially available plastics.

In the extrusion blow molding process, a plastic tube is formed by applying pressure to the inner contours of a tool mold. The typical feature of this type of production is the “pinch seam” at the bottom of the bottle.

This process impresses with its high-quality and long-lasting results.

Our cooperation partner Siepe also has extrusion blow molding machines.